PROTEIN HYDROLYSATES AS PLANT BIOSTIMULANTS

By: Giuseppe Colla, Department of Agriculture and Forest Sciences, University of Tuscia, Italy

email: giucolla@unitus.it

Protein hydrolysates (PHs) are a group of plant biostimulants that are produced by enzymatic and/or chemical hydrolysis and contain a mixture of peptides and amino acids. They may also contain other compounds that may contribute to their biostimulant action, such as carbohydrates, phenols, mineral elements, phytohormones and other organic compounds.

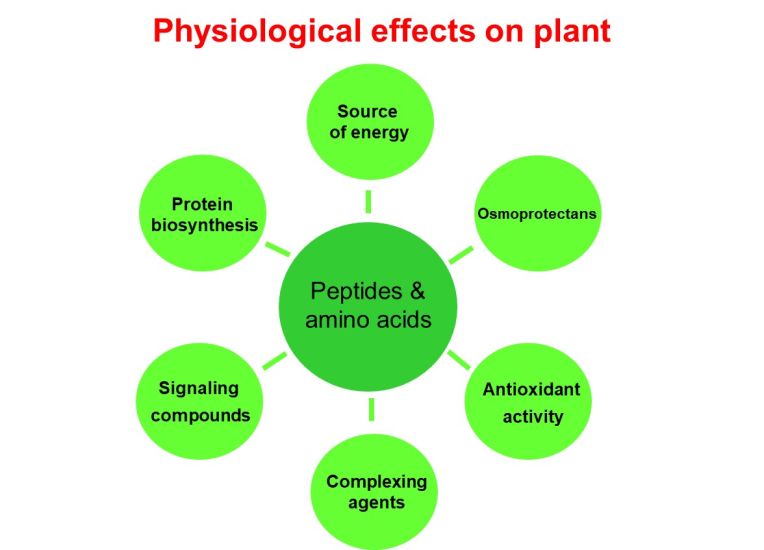

PHs have demonstrated a wide variety of benefits to crops, and they have the capability to affect multiple plant functions. In the published research article “Protein hydrolysates as biostimulants in horticulture” Colla, et al* explain in detail the many physiological processes that are affected with the application of PHs: increases of carbon and nitrogen metabolism, enhancement of secondary metabolism, up-regulation of genes encoding for nitrate uptake, and stimulation of enzymatic activities related to iron uptake from the roots (ferric chelate reductase activity). Amino acids and peptides act as complexing agents of nutrients preventing their insolubilization (more nutrient bioavailability); PHs can also stimulate fine root growth and thereby the roots capacity for nutrient uptake. Moreover, PHs can enhance soil microbial and enzymatic activities leading to an improvement of biological fertility. The above findings explain why the PHs-treated plants usually exhibit an increase of nutrient uptake and assimilation.

In the referenced article, it is also illustrated how PHs can interfere with the phytohormone balance of the plant and influence growth, development, and productivity due to the presence of specific peptides and precursors of phytohormone biosynthesis (e.g. tryptophan). Several PHs have been identified to have hormone-like activities and can elicit auxin- and gibberellin-like activities in plants stimulating seed germination, rooting, fruiting and shoot growth. In terms of product quality , PHs have been shown to improve color, texture, and nutritional value (e.g., phytochemicals) of fruits and vegetables. And application of PHs been shown to avoid or reduce crop loss caused by adverse soil conditions and environmental stress such as salinity, drought, alkalinity, and nutrient deficiency. These findings are due to several mechanisms such as: the increase of root growth and better root to shoot ratio, improvement of plant nutrition, enhancement of cell membrane stability, accumulation of osmolytes, stimulation of antioxidant defence system, and change of hormonal status.

Benefits realized by the use of PHs are generally enhanced with repeated applications and depend on many factors including the crop species or cultivar, phenological stage, environmental conditions, timing and mode of applications. PHs can be applied to crops by foliar sprays, soil application (using a microgranule application equipment or a fertigation system), and seed treatment. Foliar application of PHs is generally preferred because it allows repeated biostimulant applications over the crop growing season.

More than 90% of the PH products on the global market are based on products obtained through chemical hydrolysis of animal-sourced proteins, while enzymatically produced PHs from vegetal sources are less common.

PHs from animal proteins are typically produced using chemical hydrolysis under acid or alkaline conditions. Acid hydrolysis is an aggressive process with high temperatures that attacks peptide bonds, resulting in a high concentration of free amino acids plus the destruction of several amino acids, and possibly other useful compounds. Chemical hydrolysis may also result in racemisation, or the conversion of free amino acids from the L-form to D-form, making the PH potentially less effective or even toxic to plants. Heavy use of acids/alkalis in chemical hydrolysis will increase the salinity of the PH.

It is important for growers to carefully consider use rates. There have been some reports of phytotoxic effects and growth depression with applications of some animal-derived PH products which may be attributed to an unbalanced amino acid composition, a higher concentration of free amino acids in D-form and a high salinity. PHs from vegetal sources generally do not carry the same risk, and are safe for the crops.

Enzymatic hydrolysis is most commonly used in the production of plant-based PHs. This protein hydrolysis process is carried out by proteolytic enzymes which are more gentle than acids/alkalis and do not require high temperatures. And they commonly target specific peptide bonds, resulting in a combination of amino acids and peptides of varying length, low salinity and a consistent composition.

Peptide concentration and free amino acid contents in PHs vary widely and are dependent on the source protein and hydrolysis process utilized. Peptide concentrations are usually higher in enzymatically derived PHs than in chemically derived ones. Enzymatic hydrolysis, being more selective on where the protein is cut as compared to chemical hydrolysis, provides the industry the possibility to maximise production of bioactive peptides in PHs. These peptides act as signalling molecules modulating cell proliferation and expansion, plant reproduction, development of stomata and vascular tissues, and stress response. Signalling peptides (also called ‘peptide hormones’) are short chains of amino acids (2 to 50 amino acids) having specific amino acid sequences; one common feature of signalling peptides is that their biological activity occurs at very low concentration (nM). The last finding explains why PHs act as plant biostimulants at very low application rates (few liters per hectare).

You are invited to request access to the entire Research Article that this topic is based on here:

* Colla, Giuseppe & Nardi, Serenella & Cardarelli, Mariateresa & Ertani, Andrea & Lucini, Luigi & Canaguier, Renaud & Rouphael, Youssef. (2015). Protein hydrolysates as biostimulants in horticulture. Scientia Horticulturae.196.10.1016/j.scienta.2015.08.037.

https://www.researchgate.net/publication/282007028_Protein_hydrolysates_as_biostimulants_in_horticulture